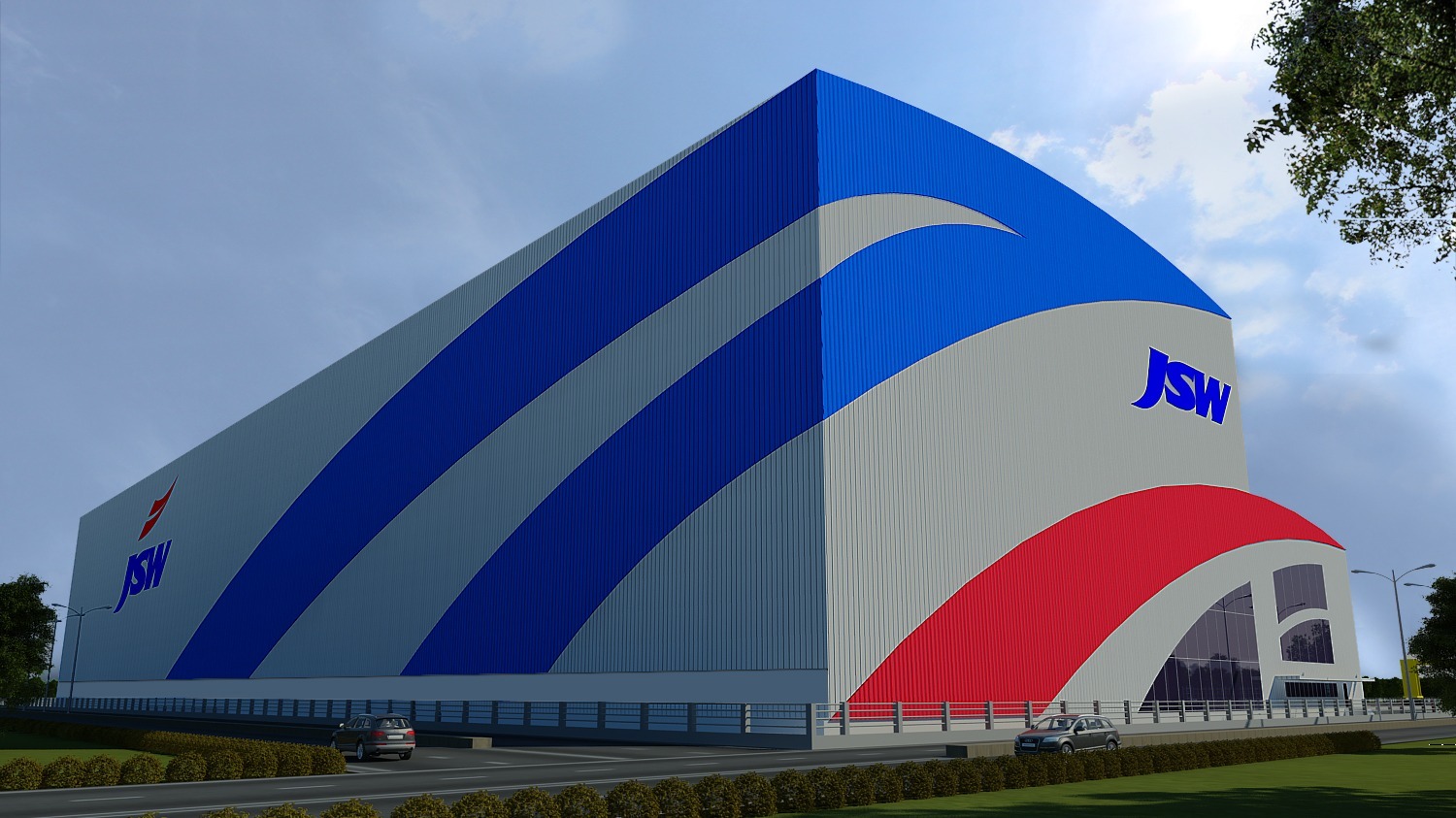

PROJECT NAME: JSW’s Central Storage Warehouse

PROJECT LOCATION: Dolvi, Maharashtra

CLIENT NAME: M/s Jindal South West (JSW)

ARCHITECTURE FIRM: M/s Aashray Design Consultants Pvt. Ltd.

STRUCTURAL CONSULTANT FIRM: M/s BMSF

ASRS CONSULTANT FIRM: M/s ThinkLink

STEEL FABRICATOR: M/S Phenix

STEEL TONNAGE: 1400 METRIC TONNES

Primary members – 50Kg/Sqm

Secondary members – 10Kg/Sqm

Sheeting & accessories – 8Kg/Sqm

CURRENT STATUS: Under Construction

PROJECT BRIEF:

Having a spread of over 1,75,000 sqft, this warehouse, located in Dolvi, Maharashtra, is the biggest central storage for JSW. This colossal warehouse is critical component in the 2000 acres land bank of JSW. The storage system in the warehouse is based on the concept of Automated Storage and Retrieval System (ASRS). This means that the compete storage and retrieval of objects in this central warehouse would be automated and will not be requiring any manual work. Ranging from a height of 2.7M to 33M, the stacks that will be stored inside the building have huge variations in height. Thus, keeping the overall budget of the project in mind, we came up with the varying height concept for the shed to counter the huge variations in the heights of the stacks. Apart from the warehouse, the shed also houses an office block for JSW.

The warehouse has a width of around 81M wide and a length of 196M. The width of the building is divided in two parts – the larger span is 57M wide and the smaller span is 24M wide. Dividing the space into two parts gives us the advantage of huge, 57M wide, column free space in the warehouse. This was a very important pre-requisite which had to be addressed for the proper functioning of the ASRS system inside the warehouse. The portals are placed at a span of 8M along the length. The heights of the pallets in the warehouse ranged from 2.7M to 33M. This gave rise to the biggest concern that we faced while designing the building, which was its colossal height. To house the 33M high pallets, we had to achieve a clear height of 37M (at ridge) inside the shed. This meant that the building would have a huge façade and this huge façade would face extreme amount of horizontal forces in the form of wind load. To arrest this unwanted uplifting force in the floor diaphragm, we introduced floor piles as part of foundation system. The entire structure, which has been designed in 345 grade steel, has a very sleek PEB concept. 345 grade steel connections plates and splicing joints are also proposed at the point of contraflexure to ensure adequate strength in the structure. Thus, with a total of 1400 Metric Tonnes of steel to be used and clear span of 57M x 37M, this project will be a one of a kind, landmark project in the field of PEB and steel structures.